Grease Duct Access Doors Code

To provide easy access into high temperature air ducts and grease duct systems.

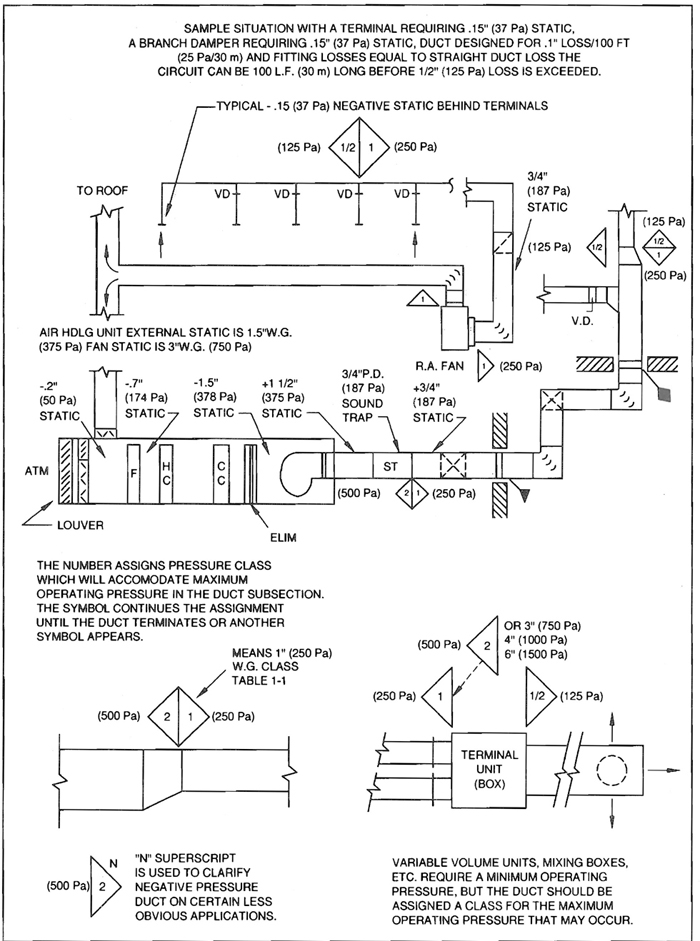

Grease duct access doors code. If you have a different exhaust system installed at some point you can reinstall the same doors and enjoy the same benefits. On site welded grease ducts must be wrapped in two layers of insulation tested to ul 2221 standards at the construction site ul 2221 classifi ed prefabricated stainless steel grease ducts no longer have to be contained in a fi re rated shaft. The f2 grease duct sandwich access door is for grease duct applications and meets nfpa 96 standards. This door was designed for applications requiring ul 1978 listing.

To provide easy access into grease duct. The primary impact the code changes may have on grease duct selection is cost differentiation. Experience multiple benefits when choosing our grease duct access panels from acudor and elmdor. Once you have the grease duct access doors in place and fitted firmly these will prevent any grease from dripping or leaking out.

F2 grease duct sandwich access door. Its ceramic fiber gasket allows its use with temperatures up to 2300 f. To prevent grease build up which can be a fire hazard access to grease ducts is necessary. 7 4 1 3 openings on horizontal grease duct systems shall be provided with safe access and a work platform when not easily accessible from a 3 m 10 ft stepladder.

Sections of grease ducts that are inaccessible from the hood or discharge openings shall be provided with cleanout openings. Sandwich access door for grease duct or high. Grease duct access doors. The gdd is a ul and ulc listed access door for installation into grease.

Grease duct cleanouts and openings shall comply with all of the following. The right access panel should be installed in order to allow service personnel safe and convenient entry to these ducts. Best access doors recommends the ba gdd grease duct access doors that are perfect for application in commercial kitchen exhaust systems. Access door application approval resides with the authority having jurisdiction.

7 4 1 4 support systems for horizontal grease duct systems 609 mm 24 in and larger in any cross sectional dimension shall be designed for the weight of the ductwork plus 363 kg. The cleanliness of your ductwork system is highly dependent on the access that your kitchen exhaust cleaning professional has to it. A huge benefit of these doors is that removing them is just as easy. Grease ducts shall not have openings except where required for the operation and maintenance of the system.

A 1 1 1 these requirements include but are not limited to all manner of cooking equipment exhaust hoods grease removal devices exhaust ductwork exhaust fans dampers fire extinguishing equipment and all other auxiliary or ancillary components or systems that are involved in the capture containment and control of grease laden cooking.