Girt Size For Metal Siding On Stud Wall

Steel roof purlins and wall girts are produced and available in house.

Girt size for metal siding on stud wall. Other spacing available. Welded together they can be used as columns braces and ties. Sub girts are a type of continuous cladding attachment solution that consists of galvanized steel framing members typically in 18 to 20 gauge profiles which attach vertically or horizontally to the structural wall. Available in 1 1 1 2 2 2 1 2 3 depths and 10 standard length.

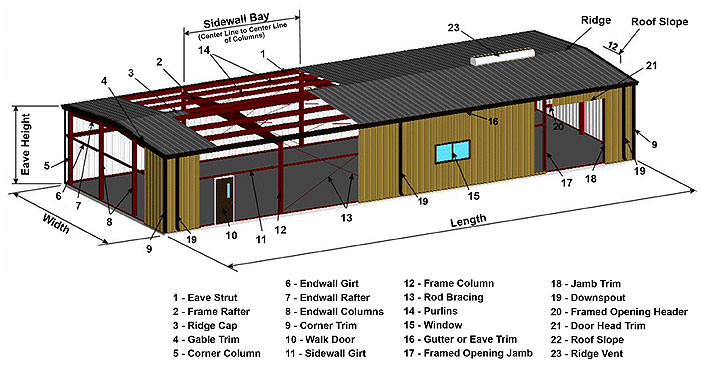

The shape of cee purlins does not allow end lapping they are butted together. Flush girts with girt face in the same plane as column face. Girt clips welded to frame. Steel z purlins and z girts are also available with other depths and flange widths.

Cee purlins are secondary steel framing members most commonly used as roof purlins wall girts and header jamb and sill for windows and doors on metal buildings. Girts are perpendicular to. Cees and zees cee or zee note. Combinations of size gauge spacing.

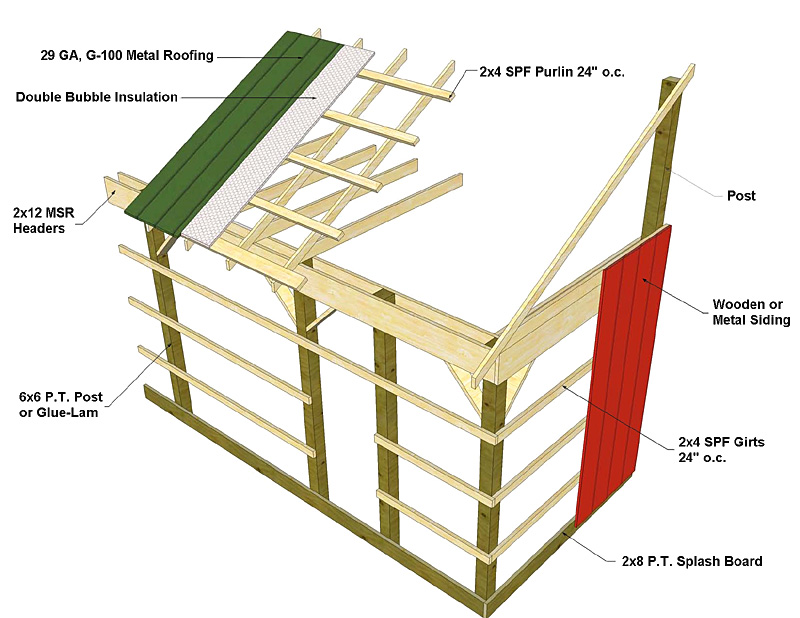

A 2 nominal lumber thickness provides the maximum pullout values for both screws and nails when the fasteners penetrate a. We manufacture any component from 1 2 steel subgirts to 12 section up to 10 gauge. The bottom of any siding or wall sheathing will be attached to this. Greater interior clearance easier interior finish.

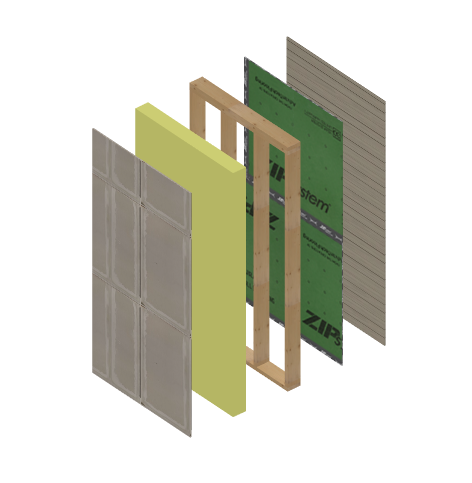

For example to obtain an r value of r 13 minimum to meet ashrae zone 1 steel girts require and external r 20. Contact flexospan for information on custom purlin and girt structural steel dimensions. You anchor the top and bottom to steel track of matching width which only comes in 10 ft. Optimum design and economical pricing.

Standard girt spacing first girt at 7 3 3 4 and maximum of 6 there after. Whereas armatherm girts require only r 10. Steel studs are sold in a variety of widths comparable to dimensional lumber sizes lengths and metal stud gauges the lower the gauge number the thicker the steel. 2x4 or 2x6 horizontal framing member nailed from post to post.

If steel siding is fastened directly to the treated skirt board a barrier of. Metal lath should be installed perpendicular to the z furring. Building felt house wrap window wrap or other non metal flashing is recommended between the two. Cladding wall assemblies can meet the r value requirements of all.

Higher effective wall assembly r values are achieved using lower values of external insulation. There are numerous cladding attachment systems designed for use with exterior insulation. Purlins girts and roof deck the substructure to which the metal panels are fastened must be properly spaced and sufficiently thick to provide a roof or wall system able to meet required design loads. Custom sizes and lengths available.

1 1 4 wide flange for easy screw attachment toed in leg to grip rigid insulation positively.