Gi Sheet Metal Properties

Zinc weathers at a very slow rate so the coating generally has a long life.

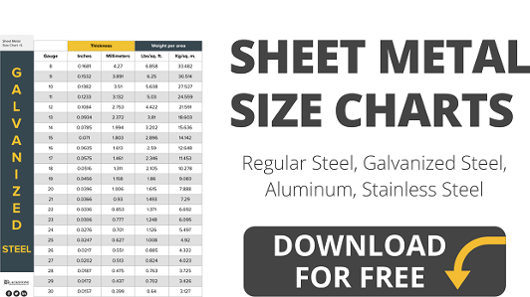

Gi sheet metal properties. Sheets of metal beyond a few micrometres in thickness appear opaque but gold leaf transmits green light. It is the maximum stress that the sheet metal material is subjected to before pulling out. Metals in general have high electrical conductivity high thermal conductivity and high density. It is the maximum stress that the cross section is subjected to when the load is applied between the two points of the specimen.

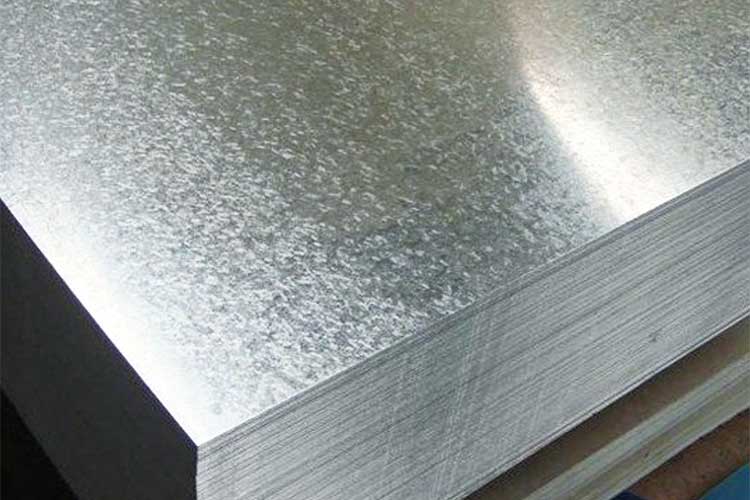

Type of rolling operation hot rolling or cold rolling operation also has an impact on sheet metal material properties. In terms of optical properties metals are shiny and lustrous. The zinc protects iron by corroding first. The zinc coating when intact prevents corrosive substances from reaching the underlying steel or iron.

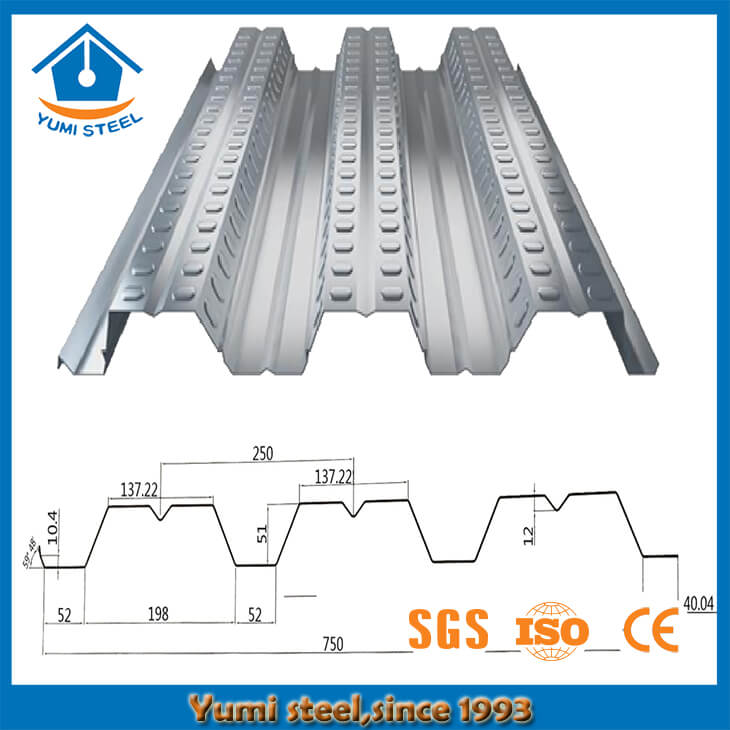

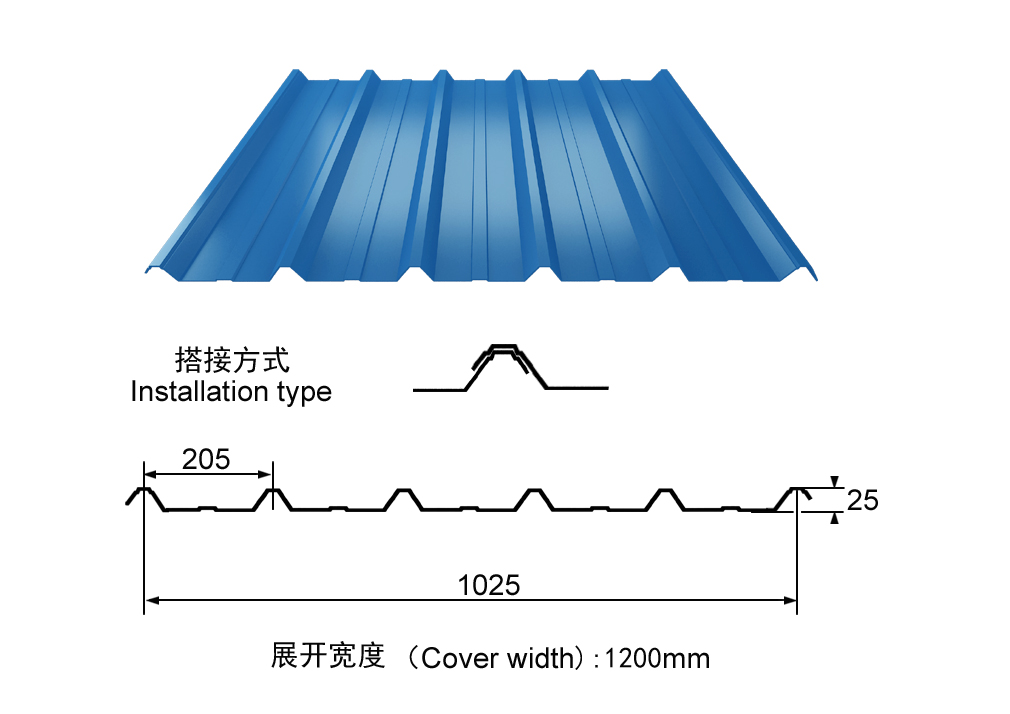

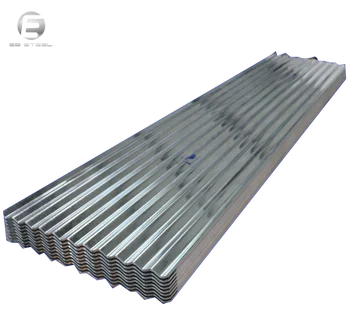

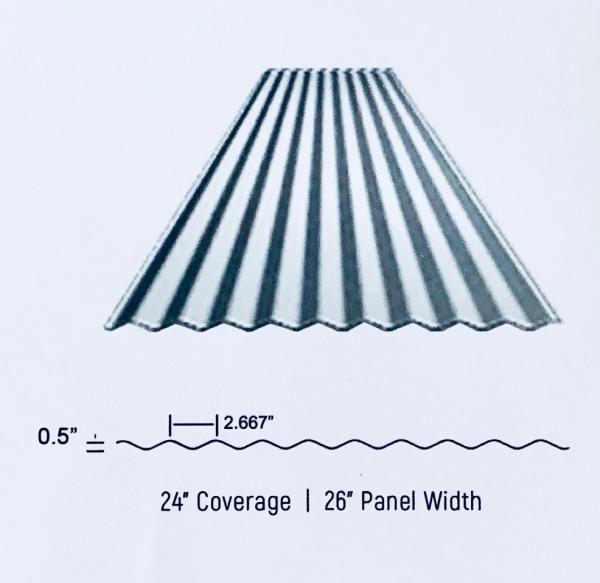

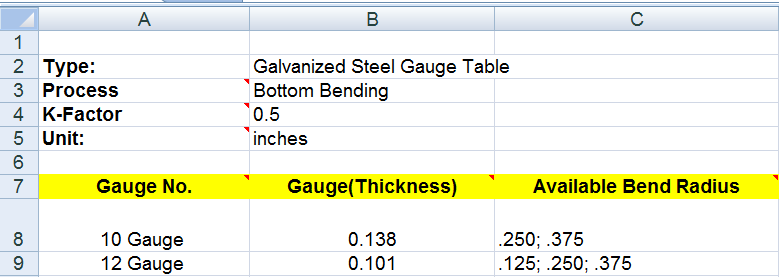

Various sheet metal material grades are available in the market. Corrugated metal made from galvanized steel or galvanized iron gi are the common materials available but it s also available in other metals like aluminum and copper which are a more expensive option. It is one of the indexes of metal strength. Galvanized iron gi sheets are steel sheets which are basically coated with zinc and include a range of hot dip galvanized and electro galvanized steel sheets.

Typically they are malleable and ductile deforming under stress without cleaving. Following are some of commonly. N mm2 or mpa the symbol is σb. Galvanizing protects the underlying iron or steel in the following main ways.

For better results application of chromates over zinc is also seen as an industrial trend. Gi sheets find uses in every sector of the economy from agricultural to industrial and constructional activities.